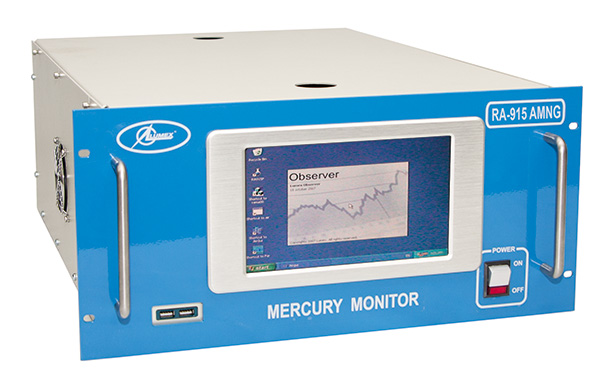

Mercury Monitor RA-915AMNG

Mercury Monitor RA-915AMNG

RA-915AMNG monitor for natural gas allows direct rapid analysis of mercury in natural gas, enables prompt reaction to variations of mercury concentrations in the stream, monitoring of the MRU units and other applications.

Mercury Monitor RA-915AMNG

RA-915AMNG monitor for natural gas allows direct rapid analysis of mercury in natural gas, enables prompt reaction to variations of mercury concentrations in the stream, monitoring of the MRU units and other applications.

RA-915AMNG monitors are designed for continuous mercury measurements in a natural gas stream and are ideal for permanent unattended installation at the gas monitoring stations.

RA-915AMNG monitor for natural gas allows direct rapid analysis of mercury in natural gas, enables prompt reaction to variations of mercury concentrations in the stream, monitoring of the MRU units and other applications.

The RA-915AMNG monitor requires very little maintenance and attention from the plant personnel (service may be done during maintenance shutdown) and requires no reagents/consumables for operation (only filters and lamp require periodic replacement during planned maintenance).

The remote data transfer makes it possible to connect the monitor to data collection systems via RS232, Modbus, and analogue output.

Atomic absorption with Zeeman background correction.

- direct continuous measurements

- low detection limit and wide range of measurement

- highest selectivity

- long-term calibration stability

- no chemicals, carrier and zero gases

- automatic zero drift and span correction

- automatic recalculation to standard conditions

- auto control and preventive maintenance functions

- robustness and low maintenance

- customized configuration

The RA-915AMNG monitors are designed for indoor operation or installation in climate controlled cabinets. The monitors can be installed in standard 19 inch rack.

- RA-915AMNG Air Mercury Monitor

- On request monitors may be equipped with a flow switching device for multiple sampling points

All of the Lumex equipment is covered by a 12-months warranty.

On customer’s request our service engineers can carry out installation and commissioning of the Lumex instruments at customer’s site. Consultations and initial training of attendance personnel are provided with due account of customer’s specific needs. Spare parts are delivered and repair is made immediately upon customer’s request (free within the warranty period).

|

Range I |

Range II |

Range III |

|

|

Measurement range |

0–2 000 |

0–150 000 |

0–3 000 000 |

|

Detection limit |

1 |

50 |

500 |

|

Averaging interval |

5 min |

Optional > 2 sec |

|

|

Zero drift correction |

Automatic |

||

|

Span drift correction |

Automatic |

||

|

Sampling gas condition |

|||

|

Gas pressure |

Atmospheric (+/-20%) |

||

|

Flow rate |

4–10 lpm |

0.5–10 lpm |

|

|

Gas humidity |

Dew point < 10 °C |

||

|

Gas temperature |

+1 to +40 °C |

||

|

Concentration of Н2S |

≤ 50 mg/m3 |

≤ 200 mg/m3 |

≤ 1000 mg/m3 |

|

Concentration of benzene |

≤ 10 mg/m3 |

≤ 200 mg/m3 |

≤ 2000 mg/m3 |

|

Concentration of mercaptans |

≤ 50 mg/m3 |

≤ 200 mg/m3 |

≤ 1000 mg/m3 |

|

Concentration of aromatic compounds |

≤ 200 mg/m3 |

≤ 2000 mg/m3 |

≤ 10000 mg/m3 |

|

Data communication |

|||

|

Communication ports |

4-20 mA current loop; 2 USB; RS 232; LAN |

||

|

Communication protocols |

Standard: GESYTEC protocol, Modbus |

||

|

Status outputs |

WORK, SERVICE |

||

|

Dimensions, Weight, Power requirements |

|||

|

Power |

110/220 V, 50/60 Hz; 120 VA |

||

|

Dimensions |

600 x 480 x 220 mm |

||

|

Weight |

20 kg |

||